News

Feature-Tec Macvital® | Efficient Cooling Water Filtration

2025-07-18

What is Cooling Water?

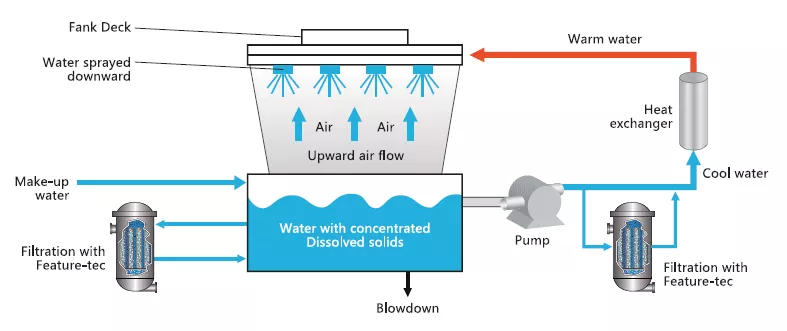

"Cooling water" refers to water or aqueous solutions used in industrial production, machinery operation, and energy conversion to absorb or transfer heat, ensuring that systems or equipment operate within optimal temperature ranges. It circulates to dissipate excess heat, preventing overheating damage and ensuring stable, safe production processes. Based on whether it contacts the cooled material, cooling water can be categorized into:

- Once-Through Cooling Water: Drawn directly from natural water sources (e.g., rivers or lakes), it is discharged after heat absorption. While cost-effective, this method causes thermal pollution and is increasingly restricted in regions with strict environmental regulations.

- Recirculating Cooling Water: Cooled via cooling towers and recirculated back into the system. It is the mainstream method in modern industry due to its high efficiency and reduced water consumption. Corrosion inhibitors and scale inhibitors are often added to maintain system performance.

Feature-Tec has extensive experience in purifying recirculating cooling water. Industrial cooling water typically accounts for 50–60% of municipal water consumption. Power plants, chemical plants, and metallurgy industries consume large volumes of cooling water for heat exchange. However, during system operation, evaporation and wind loss concentrate the water, raising ion content, altering pH, and degrading water quality. These conditions promote microbial growth and algae proliferation, especially under sunlight exposure in cooling towers—making water treatment essential for controlling scaling, corrosion, and biological fouling.

Traditional Filtration vs. Feature-Tec Macvital® Automatic Backwash Filtration

Traditional systems like sand or multimedia filters suffer from high water consumption during backwashing and cumbersome maintenance with filter media requiring frequent replacement and difficult waste disposal. In contrast, Feature-Tec’s Macvital® system offers:

- High flow rate design

- Superior filtration efficiency

- Ultra-low backwash water consumption

- No solid waste generation

Making it an ideal replacement for conventional sand and multimedia filters in industrial cooling systems.

Performance Comparison: Macvital® vs. MMF (Multimedia Filters) (Design Flow Rate: 260 m³/h)

|

Parameter |

MMF Filter |

Macvital® Automatic Backwash Filter |

|

Dimensions (L×W×H) |

11m × 3.5m × 4.5m |

4.5m × 2.3m × 2.5m (with backwash unit) |

|

Filtration Area |

30 m² |

352 m² |

|

Foundation |

Requires concrete foundation |

Not required |

|

Media Replacement |

45 tons solid waste |

52 cartridges, < 50 kg |

|

Disposal |

Waste treatment required |

Direct incineration, no extra cost |

|

Backwash Activation |

Time-based |

ΔP and time-based |

|

Maintenance Downtime |

Up to 1 week |

< 1 hour |

|

Operating Cost |

High O&M cost |

Lower long-term cost |

|

Filtration Precision |

10–20 µm |

Up to 1 µm |

|

Backwash Duration |

10–15 minutes |

< 1 minute |

|

Backwash Water Loss |

~5% of total processed fluid |

< 1% due to compact size |

|

Water Quality Requirements |

SS < 50 mg/L |

No specific requirements |

|

Pre-Filtration |

Required |

Not required |

|

Expandability |

Poor (requires civil work) |

Modular, easily scalable |

|

Chemical Dependency |

Requires coagulants |

Not required |

Dual Technology Integration: Macvital® + Jumbo High-Flow Cartridges

Feature-Tec’s proprietary automatic backwash system comprises filters, valves, sensors, pumps, and electrical controls. It is a critical component in liquid filtration and water treatment, engineered to replace traditional sand filters.

Filter Type Comparison

|

Filter Type |

Particle Removal Range |

Backwash |

Water Consumption |

Maintenance |

Space Requirement |

|

Sand Filter |

20–50 µm |

✓ |

+++ |

+++++ |

+++++++ |

|

Multimedia Filter |

5–20 µm |

✓ |

+++ |

++++ |

+++++ |

|

Feature-Tec Macvital® |

≥1 µm |

✓ |

+ |

+ |

+ |

Combined with Jumbo high-flow cartridges, the Macvital® system significantly improves both filtration efficiency and precision.

Macvital® Backwash Filter System – Specifications

|

Units |

Flow Rate (m³/h) |

Cartridge Quantity |

Filtration Area (m²) |

Dimensions (L×W×H, m) |

|

1 |

65 |

13 |

88 |

1 × 1.2 × 2.5 |

|

2 |

130 |

26 |

176 |

2.7 × 1.2 × 2.5 |

|

4 |

260 |

52 |

352 |

2.7 × 2.3 × 2.5 |

|

6 |

390 |

78 |

528 |

4.5 × 2.3 × 2.5 |

Backwash Unit (Optional)

Integrates water tank and pump for automated cleaning, prolongs filter lifespan and reduces manual maintenance.

|

Component |

Specification |

|

Unit Dimensions |

2.3 × 1.8 × 2.5 m |

|

Tank Volume |

1.5 m³ |

|

Inlet/Outlet Size |

DN100 |

|

Tank Diameter |

DN1000 |

|

Pump Flow Rate |

160 m³/h |

|

Pump Head |

33 m |

|

Power Supply |

22 kW @ 380V/50Hz |

Jumbo High-Flow Cartridges

Feature-Tec Jumbo cartridges are large-diameter, single-open-end pleated filters available in general and high-temperature types. Their inside-out flow design and pleated structure maximize dirt holding capacity, extend service life, and reduce operating costs. The absolute-rated options ensure high filtration efficiency for demanding applications. The design also reduces risk bypassing and improves consistency.

Applications Beyond Cooling Water

Feature-Tec's industrial water filtration expertise extends to:

- Drinking water

- Boiler feedwater

- Condensate filtration

Industries Served:

- Food & Beverage: Beer, wine, HFCS, soft drinks, dairy, juice, bottled water, RO pre-treatment

- Fuel & Chemicals: Refineries, amines, specialty chemicals, oil recovery, polymers

- Microelectronics: Semiconductors, process chemicals

- Energy: Nuclear, cogeneration

- Water Treatment: RO, centralized supply, municipal, seawater desalination, side-stream cooling tower filtration

About Feature-Tec

Feature-Tec is a globally recognized provider of filtration and separation solutions, integrating R&D, engineering, manufacturing, and validation. With over 20 years of industry expertise, we operate two production bases (Shanghai, Wuxi) and six offices across China and Southeast Asia.

Our Testing & Validation Center, established in 2017, is CNAS accredited and compliant with CNAS/ISO17025 and GMP-like systems.

Industries Served:

Semiconductors, automotive, food & beverage, biopharma, chemicals, water treatment, oil & gas, machining, renewable energy, marine equipment.

Product Range:

Cartridges, filter bags, filter cloths, automated filtration systems, magnetic separators, bag filters, cartridge housings, machining fluid filters, single-cartridge filters, gas-liquid separators, and specialized filtration technologies.

📩 For inquiries about cooling water filtration systems, Macvital® backwash filters, or Jumbo cartridges—including full catalog and technical specifications—please contact Feature-Tec.

Contact

Hotline: (+86)400-820-6150

Email: marketing@feature-tec.com

Address: 8/F, Block A, Building 3, Tianhua Information Technology Park, 299 Longcao Road, Xuhui District, Shanghai

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.