News

Feature-Tec's Liquid Waste Silica Recovery Solution

2025-07-10

Liquid waste silica recovery refers to the separation, purification, and reuse of wastewater or other liquids containing nanoscale or microscale silica particles generated during industrial processes. This recovery technology is widely applied in high-end manufacturing and high-purity material-related industries and processes, including:

- Semiconductor industry (e.g., wafer fabrication)

- Solar photovoltaic industry (e.g., polysilicon/ingot processing)

- Microelectronics and high-purity material manufacturing

- Precision optics and LED sectors

- Waste liquid resource recycling

- Cutting and grinding fluid treatment

Selfclear + Dycera Dynamic Membrane System – Customized for Flexible Conditions

Feature-Tec has designed a silica-containing wastewater recovery process using a purely physical solid-liquid separation and slurry concentration method, ensuring system reliability and operational stability. This system not only saves large volumes of water annually but also significantly reduces the consumption of flocculants and coagulants, as well as the volume of sludge generated in conventional wastewater treatment facilities.

Core Equipment:

- Dycera Dynamic Membrane Filtration System

- Selfclear High-Capacity Filtration System

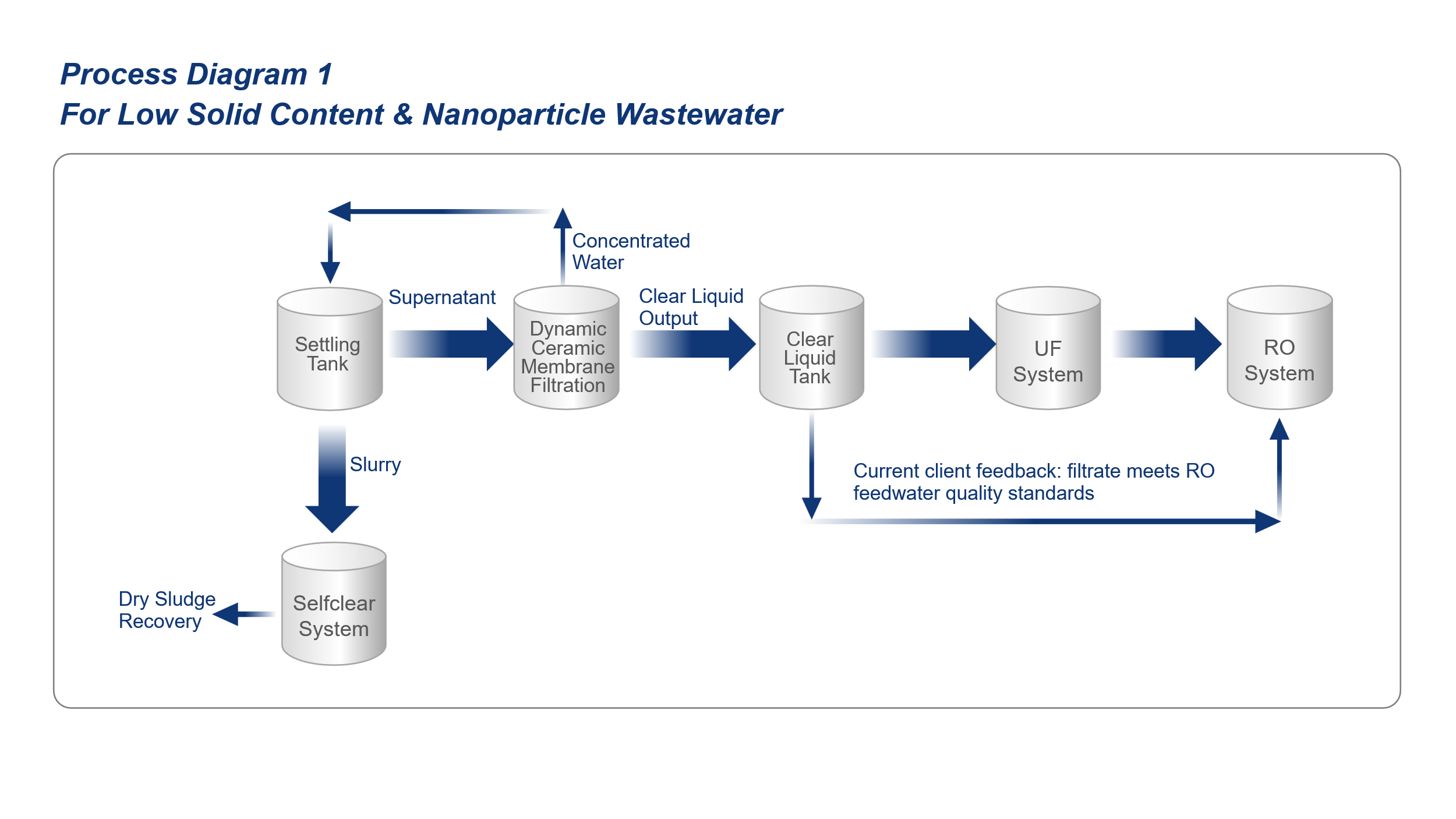

Process Route 1:

For nanoscale particles and low solid content conditions

→ Primary Dycera + Bypass Selfclear

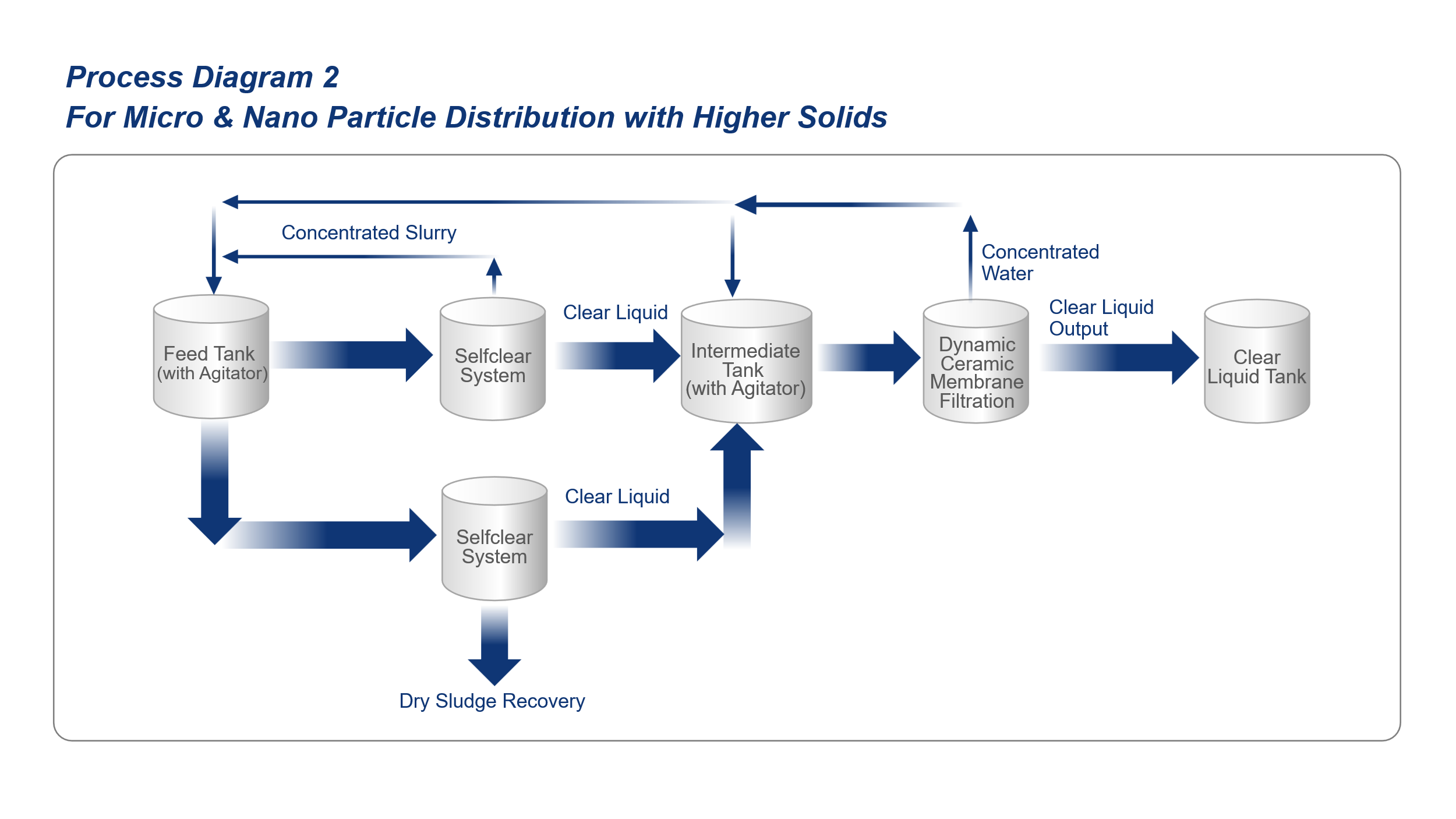

Process Route 2:

For micro + nano particles (normal distribution) and moderate solid content

→ Primary Selfclear + Secondary Dycera

Conventional Treatment vs. Feature-Tec Upgraded Technology

|

Comparison Items |

Traditional Treatment Process |

Feature-Tec Upgraded Process (Selfclear + Dycera) |

|

System Configuration |

Pre-treatment + Desludging + Plate Frame + TMF |

Selfclear + Dycera |

|

Filtration Mode |

Full-flow filtration |

Precision filtration |

|

Filter Elements |

Gravity sedimentation/cartridge + filter cloth/tubular membrane |

Cluster tube + filter cloth / dual-round membrane |

|

Filtration Precision |

Micron level |

Micron / Nanometer level |

|

Feedwater Requirements |

Requires pH adjustment and separation of organics/oils; membrane flux easily declines |

No chemicals needed; Dycera membranes are ideal for fine particles and low concentration |

|

Flux Stability |

Flux affected by chemical dosage fluctuations |

High-shear surface flow prevents clogging; more stable flux |

|

Cleaning Method |

Manual/online cleaning (high frequency) |

Online cleaning; no manual intervention or low frequency |

|

Effluent Quality |

Depending on membrane performance |

Meets discharge standards directly |

|

Solid Phase Status |

Requires post-concentration dewatering |

Cake form: no further dewatering needed |

|

Operating Environment |

Open, dusty, unpleasant odors |

Enclosed, environmentally friendly |

|

Maintenance Frequency |

Membranes prone to clogging/short life |

Enclosed membranes with long service life |

|

Labor Costs |

High |

Low |

|

Technical Adaptability |

Complex process, limited material options |

Simple process, wide material compatibility, adaptable to electrochemical systems |

|

Space Requirements |

Large footprint (settling tanks + filters) |

Modular design, compact layout, ideal for industrial deployment |

Customer Value Analysis

The "Selfclear + Dycera" hybrid recovery system by Feature-Tec is tailored for recovering nanoscale silica and colloidal impurities from wastewater through purely physical methods, achieving efficient separation and water reuse.

Customer Benefits:

- Stable effluent turbidity below 1 NTU, compliant with RO feedwater requirements

- High recovery rate of micro-silica; solid cake moisture content controlled at 40–60%

- Reliable system operation with minimal manual intervention

Feature-Tec — Green Process Enabler

Feature-Tec New Materials is a globally recognized provider of filtration and separation solutions. With over 20 years of experience, we integrate R&D, design, manufacturing, and testing under one roof. By 2025, we operate two manufacturing bases in Shanghai and Wuxi, and six branch offices in Shanghai, Beijing, Dalian, Xi’an, Hefei, and Singapore.

Feature-Tec’s Testing & Verification Center, established in 2017, is CNAS accredited (China National Accreditation Service for Conformity Assessment) and operates under compliant quality systems including CNAS/ISO17025 and GMP-Like standards.

Application Fields

Feature-Tec solutions are widely applied across:

- Semiconductor & electronics

- Automotive manufacturing

- Food & beverage

- Biopharmaceuticals

- Chemical production

- Water treatment

- Oil & gas

- Metalworking

- Green energy

- Marine engineering

We provide advanced filtration components including cartridges, filter bags, and cloths of various models and materials. Equipment offerings include:

- Fully automatic filtration systems

- Magnetic separators

- Bag filters, cartridge filters

- Machining fluid filters

- Single-core filters

- Oil-gas separation units

Specialized processes:

Catalyst recovery, Raney nickel magnetic filtration, nano slurry concentration and washing, amine desulfurization filtration, activated carbon decolorization, silicon steel pickling, comprehensive dust management, and spent acid concentration.

"Green manufacturing is not a future trend — it's the present." Feature-Tec empowers industry with leading liquid waste silica recovery and purification solutions, driving the transition toward cleaner, more efficient, low-carbon, and automated production.

Contact the Feature-Tec technical team today to transform your wastewater into a valuable resource and shape a greener future!

Next:

Contact

Hotline: (+86)400-820-6150

Email: marketing@feature-tec.com

Address: 8/F, Block A, Building 3, Tianhua Information Technology Park, 299 Longcao Road, Xuhui District, Shanghai

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.