Special Filtration Process

Filtration and Separation Breaking Boundaries in Industrial Innovation

No data

Silicon Steel Pickling Application

Problem description:

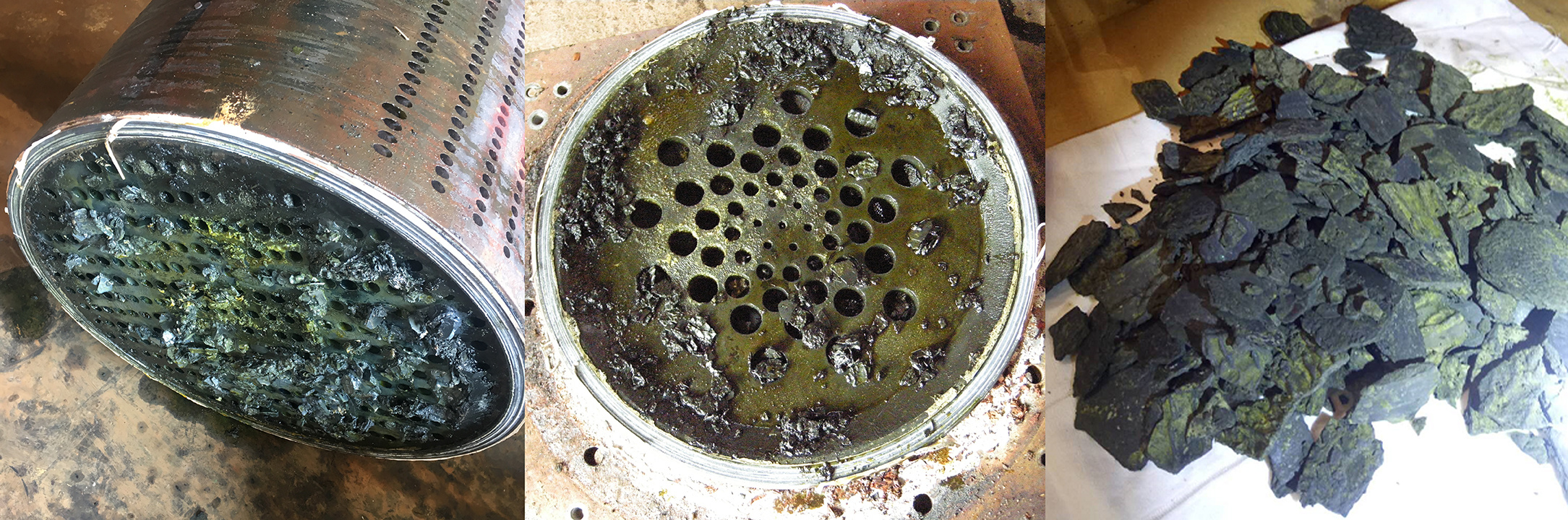

Graphite heat exchanger is a widely used heat exchange equipment in industry, mainly used for sulfuric acid, hydrochloric acid, acetic acid and phosphoric acid and other corrosive media heat exchange. However, in practical application, under the condition of multi-viscous impurities, the surface of graphite forms a resin sheet with increased roughness, which causes acid to stick to one side of the hole, dirt leads to a sharp decline in heat exchange capacity, and the blockage of graphite channels causes the production line to stop. These problems are difficult to be effectively solved.

A domestic silicon steel cold rolling mill used graphite heat exchanger in the pickling process. However, in actual operation, a large amount of silicon mud is deposited in the acid tank. Due to the presence of silicon mud caused by the graphite heater and other equipment blockage, so that the pickling cycle system flow reduction, forced to slow down or stop processing, frequent disassembly and assembly of graphite heater disintegration cleaning, seriously affecting the normal operation of the unit and the working environment. Cleaning the graphite heat exchanger is very complicated and cumbersome. It is necessary to completely disassemble the graphite heat exchanger and drill out the blocked graphite holes. However, graphite has the characteristics of brittle fracture, bending resistance and Low characteristics, easy to cause erosion defects during flushing, causing damage to equipment. The entire disassembly, cleaning, and assembly process takes 3 - 5 days, which has a non-negligible economic impact on the entire production line.

In view of the existing problems of the heat exchanger, after research, Feature-tec has formulated a plan to replace the graphite heat exchanger with the tantalum heat exchanger to solve the problems of silicon mud deposition and scaling, and frequent and cumbersome maintenance.

Product advantages:

Tantalum has good corrosion resistance, toughness, ductility and thermal conductivity, high melting point. In various inorganic acid production devices and waste acid concentration equipment, tantalum can be used to replace stainless steel, and its life is dozens of times higher than that of stainless steel. Tantalum also has excellent chemical properties and extremely high corrosion resistance. No matter under cold or hot conditions, it does not react to hydrochloric acid, concentrated nitric acid and "aqua regia. The tantalum is soaked in sulfuric acid at 200 ℃ for one year, and the surface layer is only damaged by 0.006mm. Experiments show that the corrosion resistance of tantalum is very good, and glass is very similar, in addition to hydrofluoric acid, fluorine, fuming sulfuric acid, alkali, almost all the corrosion of chemical media. This rare metal characteristics, to the application of tantalum has brought a wide range of space.

When the fouling thickness of the heat exchanger is 1mm, the heat transfer coefficient is reduced by about 10%. Therefore, reducing the fouling layer of the heat exchanger is the key factor for the long-term stable operation of the heat exchanger. The metal characteristics of tantalum greatly improve the flow rate of the acid solution, the surface of the tantalum tube for high-speed scouring, at the same time, the inner surface of the tantalum tube is very smooth, silicon mud is not easy to accumulate, to ensure the efficient and stable operation of the heat exchanger. Compared with the graphite heat exchanger, the tantalum heat exchanger is a fully welded structure, and the overall structure is stable, which changes the uncertainty caused by the brittleness of graphite in the process of lifting and installation. At the same time, in the cleaning process, it will not cause erosion defects similar to graphite due to high pressure erosion.

Application of Feature-tec Tantalum Heat Exchanger in Silicon Steel Pickling:

After the transformation, the Feature-tec tantalum heat exchanger was operated stably for 2 months, and there was no obvious scaling phenomenon during the regular inspection process, and the heat exchange was stable. Change the original graphite heat exchanger a month will appear flow, heat transfer efficiency decline. In order to ensure the normal operation of the silicon steel production line, it has brought great positive significance and considerable economic benefits.

In summary, the tantalum tube heat exchanger is a very good heat exchange equipment, in silicon steel pickling can effectively replace the graphite heat exchanger. At the same time, due to the processable characteristics of tantalum metal, it can be made into a variety of process equipment, which brings changes to the industrial fields such as organic acid production and waste acid concentration.

Related Solutions

Related components

Related components

Related Equipment

Message consultation

Contact

Hotline: (+86)400-820-6150

Email: marketing@feature-tec.com

Address: 8/F, Block A, Building 3, Tianhua Information Technology Park, 299 Longcao Road, Xuhui District, Shanghai

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.