Special Filtration Process

Filtration and Separation Breaking Boundaries in Industrial Innovation

No data

Waste Acid Concentration

Concentration and recovery of organic waste sulfuric acid has become an urgent topic for three-waste management and environmental protection.

Sulfuric acid is a crucial raw material in the chemical industry, particularly for the production of organic chemicals. However, only a small portion of sulfuric acid is utilized effectively as a substitute for the base in chemical reactions, while the majority is discharged as either dilute sulfuric acid or waste sulfuric acid.

Therefore, the concentration and recovery of organic waste sulfuric acid has become an urgent issue for waste management and environmental protection. Currently, there are several methods for concentrating waste sulfuric acid, including vacuum concentration, kettle concentration, and combustion concentration.

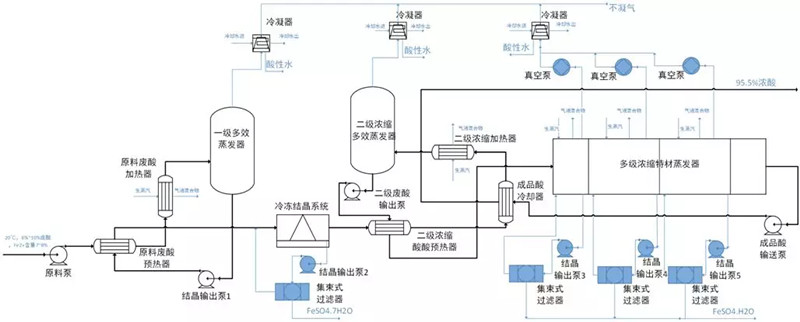

Waste sulfuric acid concentration process

Sulfuric acid and nitric acid are highly corrosive and cannot be used directly. They need to be concentrated by evaporating water from waste sulfuric acid before they can be recycled. Feature-Tec offers comprehensive solutions for waste acid concentration to help enterprises in this process.

Feature-Tec waste sulfuric acid purification, concentration and regeneration technology

After pretreatment to remove organic and inorganic salt impurities, waste sulfuric acid goes through a hot and cold acid exchanger to absorb heat energy from the finished acid. Then, it is preheated in the acid-acid heat exchanger before entering the acid evaporator. 95% of the sulfuric acid is dehydrated and cooled in the finished acid cooler before being introduced into the acid mixing section.

The water vapor generated in the acid evaporator is purified in the washing tower before being directed to the neutralization vessel. The acidic steam produced in the evaporator is treated in the washing tower for purification and subsequently cooled in the tail gas cooler. Finally, it is conveyed to the tail gas spray tower using a liquid ring vacuum pump.

Features of Feature-Tec waste sulfuric acid concentration and regeneration technology

Feature-Tec offers advanced solutions for the concentration and recovery of organic waste sulfuric acid, ensuring maximum concentration of sulfuric acid.

Feature Tec Waste Acid Concentration and Crystallization Treatment

1、Achieve a high concentration rate of waste acid, surpassing 95%, enabling the acid solution to be reused effectively.

2、Ensure thorough separation of concentrated ferrous sulfate, resulting in high purity of sulfuric acid.

3、Utilize a variety of superior anticorrosive materials to prevent equipment corrosion and minimize the need for frequent replacements, significantly reducing labor intensity.

4、Implement a unique pre-treatment technology that offers a high recovery rate of titanium dioxide.

5、Leverage a stable and reliable system with the utilization of unique special materials technology.

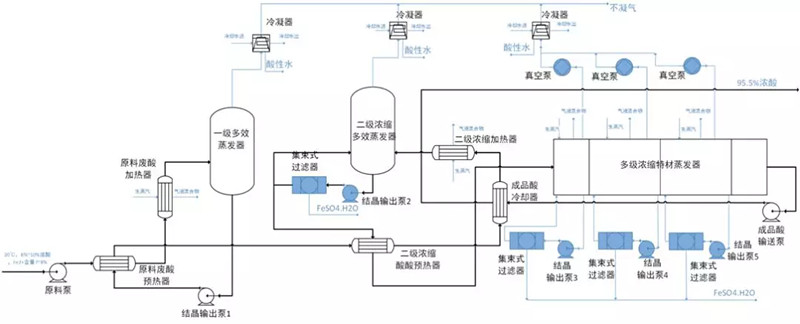

Feature-Tec special material production technology

Feature-Tec's special material production technology ensures the stable operation of waste sulfuric acid concentration devices for extended periods of time by addressing the high maintenance and replacement costs associated with the strong corrosiveness of waste sulfuric acid. The selection of acid corrosion-resistant materials, such as tantalum, for key equipment components like the acid vaporizer and tantalum tube heat exchanger, is a scientific and rational approach.

The main equipments of the waste sulfuric acid concentration device use tantalum material, such as acid vaporizer and tantalum tube heat exchanger.

Tantalum tube heat exchanger

Bayonet format Heaters

In addition to tantalum equipment and components, Feature Tec offers a range of other special material production technologies. These technologies assist enterprises in resolving process management issues, reducing production costs, enhancing economic efficiency, and achieving sustainable and environmentally-friendly production practices.

Related Solutions

Related components

Related components

Related Equipment

Message consultation

Contact

Hotline: (+86)400-820-6150

Email: marketing@feature-tec.com

Address: 8/F, Block A, Building 3, Tianhua Information Technology Park, 299 Longcao Road, Xuhui District, Shanghai

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.