Special Filtration Process

Filtration and Separation Breaking Boundaries in Industrial Innovation

No data

Amine Filtration in Desulfurization

The amine desulfurization Method is widely used in Refinery dry gas and LPG processing. H2S and CO2 from the gas are absorbed by the amine solution, forming an alcohol amine salt’s solution. H2S & CO2 can then be stripped from the gas through a heating process, allowing the amine to be re-generated for recycle use.

During the process of amine desulfurization, besides absorbing H2S and CO2, the amine solution may also react with other materials or carry solid particles from the pipe. These include heat-stable salts, sulfide, iron dust, etc. This may cause foaming & fouling, lower the absorption efficiency, or even damage the equipment.

Due to the problems in the process as mentioned above, amine filtration becomes an important process accompanied with gas desulfurization. Feature-tec has provided optimized solutions for amine desulfurization for years.

Problems in the Process:

-

Amine foaming in the contactor tower and stripper column, due to the reaction between a high concentration of hydrocarbons and organic acids, causes the loss of amine solvent, poisoning of catalysts, and lowers contact efficiency.

-

Liquid hydrocarbons from natural gas, FeS/SS, and chemical treatment agents cause fouling in the cooling tower and heat exchangers, thus reducing efficiency, corroding the heat exchange meter, and damaging the heat equipment.

-

Frequent amine top-ups cause increased maintenance costs. The formation of heat-stable salts and cyanide leads to fouling of the carbon bed, which in turn increases energy consumption. This also leads to increased use of anti-foaming agents, resulting in more waste production.

Reason of Amine Foaming

• hydrocarbons and organic acids.

• Treated fluid and anti-corrosion agent

• Oil, inhibitors and welding fluid

• Water contaminants

• Suspended solids (indirectly causes amine foaming)

- FeS, Carbon powder, iron oxides

- Inefficient filtration and separation of inlet flue gas

• Cotton String Wound Filter Cartridge

- Unsatisfactory filter material

Suspended Solid Causes:

• Rust, iron sulfide from sour gas pipeline due to corrosion

• Mineral deposits, Rust and pipe scale from water

• Iron sulfide, rust, pipe scale and activated carbon from activated carbon bed filter

Keys to Maintaining a Clean System

• Limit flow rate of lean amine and natural gas to reduce the carbohydrate concentration.

• Fully filtrate the incoming sour gas to reduce contaminants such as liquid hydrocarbons, FeS / SS solid particles and water.

• Ensure sufficient pre-filter and after-filter for activated carbon bed

• Select an appropriate mechanical filter material

• Use anti-foaming agent temporarily

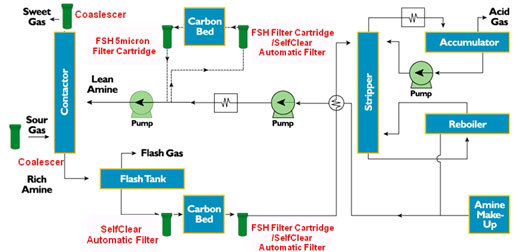

Filtration Solution of Amine Desulfurization

1. Sour Gas filtration : prior to processing the amine cleaning , the solid and liquid impurities present in the sour gas should be removed. Feature-Tec’s Coalescer filter will be able to filter off and intercept the solid and liquid impurities such as Iron sulfide, rust, etc efficiently.

2. Amine recovery: A coalescer can be installed to recover the amine carried over by the gas, to reduce the loss of amine and cut the maintenance costs.

3. Amine foaming prevention: The FSH Filter Cartridge which provides high dirt holding capacity be applied to the rich amine and lean amine solution filtration, removing the solid particles, and run through the activated carbon filter to remove the gas in the amine solution. This helps to prevent amine foaming, thus protecting the downstream equipment.

4. Feature-Tec's Selfclear is the best solution to deal with rich amine filtration to remove small and deformed particles.

Feature-Tec Amine Desulfurization References

Before and After Filtration

Customer: China National

Offshore Oil Corporation (CNOOC)

Filtration application:

Amine Filtration

Design Features:

SelfClear Filter System

Characteristics of Cluster Amine Purification System

|

Advantages |

Features |

|

Consistent Filtration Efficiency |

• Usage of patented cartridge structure to ensure the stability of pressure around the cartridge, causing the filter cake to formed evenly. |

|

Efficient Backwash Energy & Water Conservation |

• Patented design of the back flushing system requires only 0.2 - 20 min to complete under normal circumstances, and water consumption is less than 0.5% of filtrate fluid, removing even sticky solid particles. |

|

Automatic control of continuous filtration |

• Automatic PLC control, touch screen operation, fully automatic, semi-automatic and manual operating modes are available. |

|

High Corrosion Resistance |

• Wide choices of materials for the system providing resistance to chemicals, acids, alkalis, salts, solvents and etc. |

|

Long service Lifespan System at Low Operating Cost |

• ISO 9001 quality system applied to all manufacture procedures including materials, accessories and suppliers. 100% overall operation tests are performed before delivery. |

|

Small Space Requirement |

• Option for modular system which can be installed in a configuration which will comply to space restraints |

|

Strong technical support |

• Feature-Tec's experienced engineers provide comprehensive pre and post sales technical support and services |

Related Solutions

Related components

Related components

Related Equipment

Message consultation

Contact

Hotline: (+86)400-820-6150

Email: marketing@feature-tec.com

Address: 8/F, Block A, Building 3, Tianhua Information Technology Park, 299 Longcao Road, Xuhui District, Shanghai

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.